Across ancient landscapes, remarkable crafts once shaped empires, guided explorers, and colored entire cultures. Many of these skills were so advanced that modern science is only now beginning to understand how they worked. From self-healing concrete to pigments that defied time, our ancestors mastered techniques that blended intuition, experimentation, and precise engineering. Exploring these rediscovered secrets offers a fresh look at human creativity and reminds us that innovation has always been part of our story.

1. Roman Self-Healing Concrete

The Romans developed concrete that endures in sea walls and monuments by combining volcanic ash with lime and seawater. Evidence now suggests lime fragments and reactive volcanic glass triggered mineral growth inside microcracks, gradually sealing damage and granting a kind of self-healing. That mix created marine concrete resistant to erosion and chemical attack, which helped ports and piers survive centuries. Today, researchers study those ancient recipes to inspire more durable and sustainable modern mixes and to reduce maintenance needs.

2. Egyptian Blue Pigment Engineering

Egyptian artisans synthesized a vivid blue by heating silica, lime, copper, and an alkali to form a stable calcium copper silicate. That pigment could be used in paint, glaze, and inlay, and remained colorfast under sunlight for centuries. Making it required controlled high temperatures and an understanding of raw-material proportions, firing atmospheres, and cooling regimes. Archaeologists study furnace traces and residual minerals to reconstruct how early technologists tuned temperature and chemistry to produce a reliably brilliant blue.

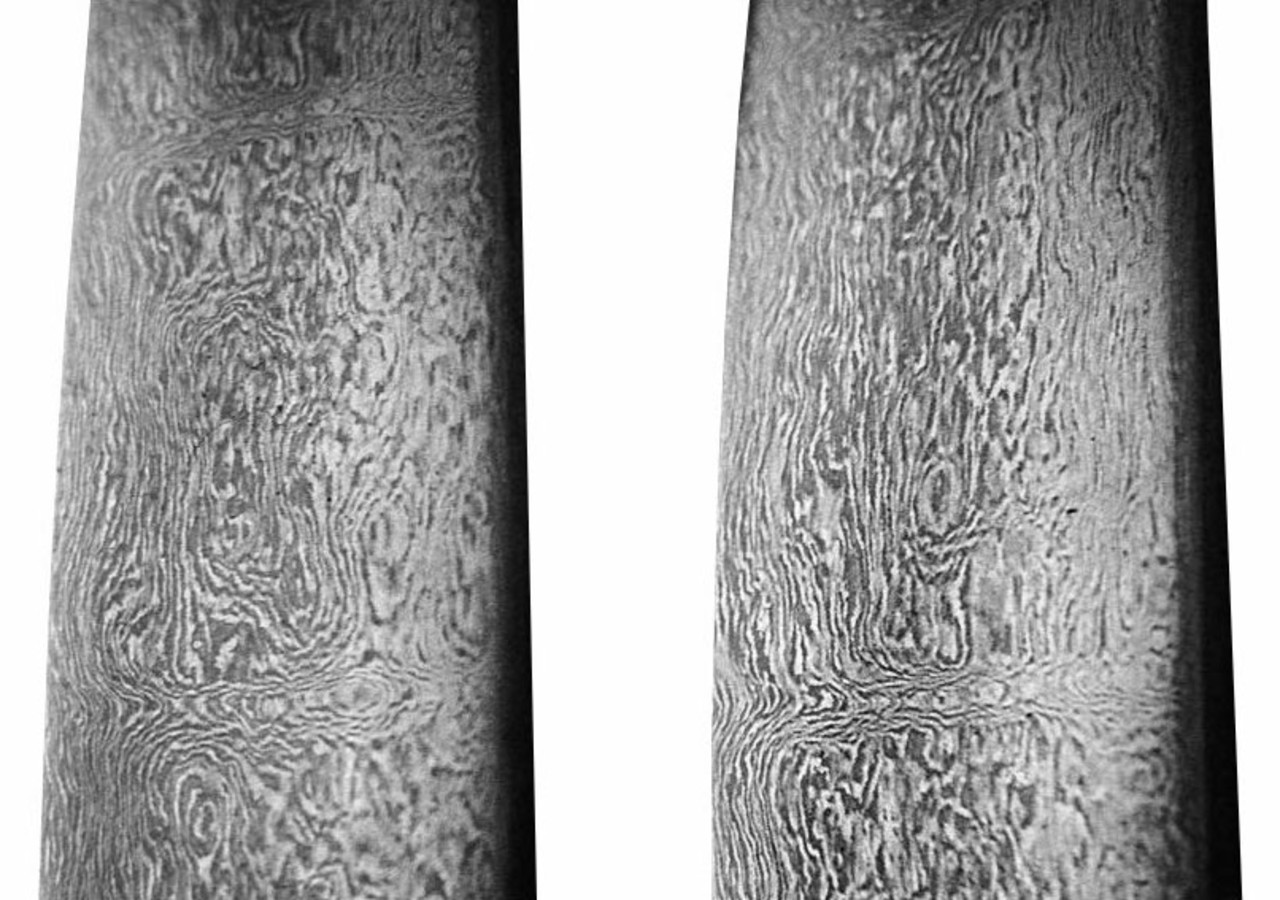

3. Damascus Steel’s Lost Metallurgy

Wootz crucible steel, the precursor to historic Damascus blades, was produced by melting iron and carbon-rich materials in sealed crucibles to yield high-carbon ingots. Careful control of temperature, ore selection, and carbon sources created distinctive banded microstructures and remarkable mechanical properties. Analyses of surviving blades reveal patterned carbides and traces consistent with slow solidification and carbon transfer. The exact craft combined metallurgy, specific raw materials, and forging know-how, producing swords prized for sharpness, toughness, and unique patterned surfaces.

4. Persian Glazed Brickwork Techniques

Persian builders mastered glazed brickwork by fusing silica-rich bricks with mineral-based glazes that produced vibrant blues, yellows, and greens. By controlling kiln temperatures and using metal oxides, they created durable surfaces that resisted fading and weathering. Relief bricks were carefully molded before firing, allowing palaces and ceremonial gateways to display vivid scenes of warriors, animals, and mythic symbols. These techniques required strict temperature control, precise material ratios, and skilled artisanship, revealing an early fusion of chemistry, art, and architectural engineering.

5. Viking Sunstone Navigation

Medieval accounts and experiments suggest Norse sailors may have used birefringent crystals, such as calcite, as a “sunstone” to find the sun’s direction on cloudy or foggy days. By rotating a crystal and observing changes in polarized skylight, navigators could infer the sun’s bearing to within a few degrees, supplementing dead reckoning and coastal landmarks. Practical use required skill, seasonal knowledge of skylight polarization, and teamwork, making the sunstone an elegant optical trick that likely aided long-distance seafaring in northern latitudes.

6. Indus Valley Precision Stone Drilling

Skilled artisans of the Indus civilization drilled hard stones and produced uniformly perforated beads using bow drills, tapered bits, and abrasive slurries. Controlled rotation, steady pressure, and progressively finer abrasives allowed the creation of tiny, precise holes in agate, carnelian, and other tough materials. Evidence of standardized drill fittings and workshop remains indicates specialized production and knowledge transfer among craftspeople. This combination of tools and processes enabled remarkably consistent results across large-scale bead industries.

7. Han-Era Rust-Resistant Metallurgy

Han dynasty craftsmen reduced long-term corrosion through alloy choices and surface treatments that encouraged stable patina formation on bronze objects. Certain alloy compositions promoted protective oxide layers, while burial and storage practices limited exposure to corrosive elements. Scientific analysis of Han bronzes shows layered patinas and mineral assemblages that slow ongoing degradation, suggesting empirical knowledge about metal longevity. These methods extended the usable life of ritual bronzes, tools, and fittings and informed later metallurgical refinements.

8. Greek Fire’s Chemical Strategy

Greek fire was a Byzantine incendiary system that burned on water and was employed in naval warfare. Contemporary descriptions and experimental reconstructions point to petroleum or heavy bitumen mixed with resins, sulfur, and viscous additives to create a sticky, persistent flame delivered through siphons or thrown containers. The mixture’s composition and deployment methods were closely guarded, varied by maker and place, and its effectiveness came from chemical persistence and delivery technique rather than any single miraculous ingredient.

9. Nazca Geoglyph Construction Methods

The Nazca lines were produced by clearing dark surface stones to expose lighter subsoil, forming vast geoglyphs visible from slight elevations. Construction likely relied on simple but disciplined surveying methods: ropes, stakes, sightlines, and scaled measurements used to enlarge small designs into enormous figures and straight lines. Repeated measurement, control points, and group coordination allowed precise execution over wide areas. The result reflects organized planning, ritual intent, and practical landscape engineering rather than accidental or ad hoc drawing.